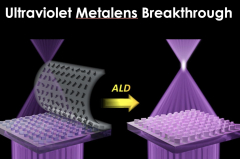

Home » Artificial intelligence » Ultraviolet Metalenses Mass Produced. Will Enable Future AI Chips

Extreme Ultraviolet lithography for computersystem chips haveactually been important to letting us effectively get muchbetter than 14 nanometer computersystem chips. Metalenses are 10,000 times thinner than routine lenses.

Metalenses control light residentialorcommercialproperties through nanometer-scale patterns or structures on lens surfaceareas. With the capability to lower the density of standard lenses by a aspect of 10,000, they hold considerable guarantee in medical gadgets that are placed in the body and wearable gadgets. Ongoing active researchstudy intends to attain mass production and commercialization of metalenses.

Researchers haveactually created a strategy for the mass production of large-area metalenses customized for usage in the ultraviolet area.

Ultraviolet light presents challenges as it is takenin by most products due to its high energy level.

The group utilized a nano-imprinting procedure that etches the pattern like a stamp. They accomplished the fast and economical production of metalenses that are 20,000 times bigger than traditional ones.

Metalenses have impressive light-modulating efficiencies, and researchstudies haveactually been performed on them to not just change traditional large and heavy refractive lenses however likewise to broaden on them. However, their operating wavelengths have hardlyever covered the ultraviolet (UV) routine giventhat UV-transparent products are limited and nanopatterning methods have a little