A group of style finishes from London’s Royal College of Art have come up with a method to make RFID tags completely from paper, with no metal or silicon parts in a quote to cut down on waste from single-use electronicdevices.

Under their start-up PulpaTronics, the group hasactually developed a chipless, paper-only variation of a radio-frequency recognition (RFID) tag – a type of electronic tracker that is connected to items and is most typically discovered in clothes shops.

These types of tags have prospered barcodes in lotsof huge sellers, where they enable self-checkout devices to “magically” determine products without scanning anything, while likewise assistingin stock management and theft avoidance.

However, these types of tags – 18 billion of which are produced every year – are “overengineered”, according to PulpaTronics.

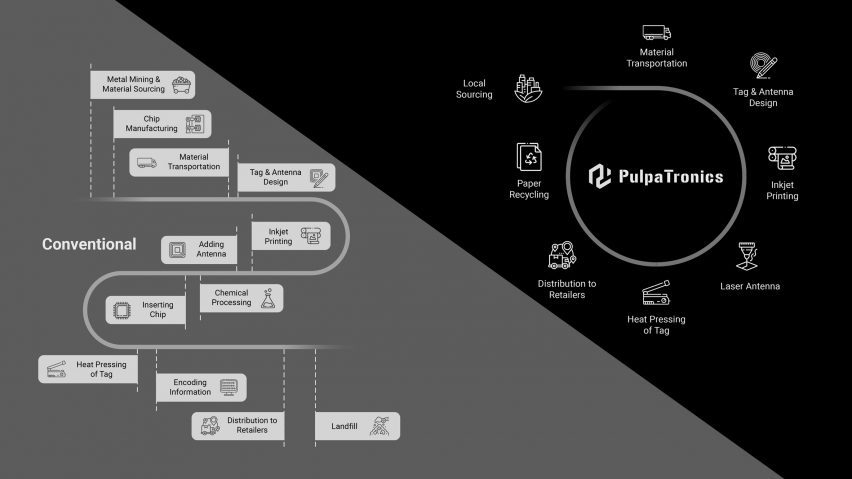

The gadgets rely on a circuit with a microchip and antenna, normally ingrained into a stickerlabel adhered to the paper swing tag. Due to the mix of paper, metal and silicon, they are unrecyclable and tend to end up in garbagedumps.

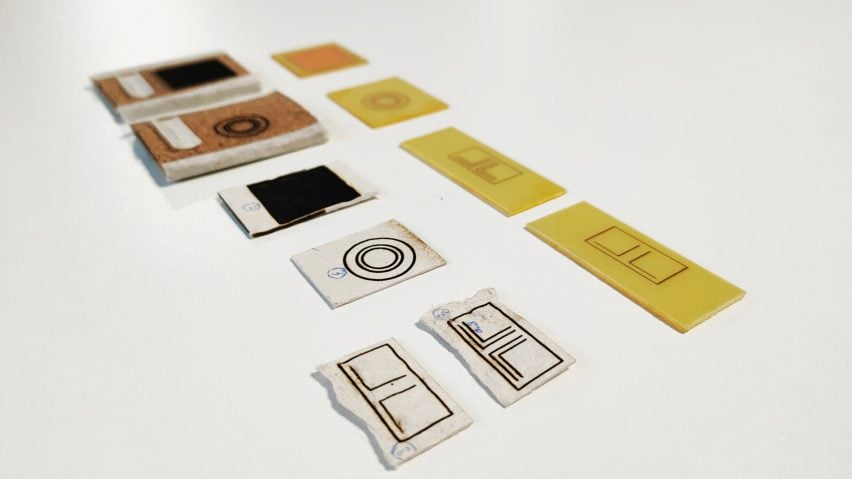

By contrast, PulpaTronics’ option RFID style needs no other product than paper. The business just utilizes a laser to mark a circuit onto its surfacearea, with the laser settings tuned so as not to cut or burn the paper however to modification its chemical structure to make it conductive.

This circuit is carbon-based and the tag can be recycled with home waste as quickly as a piece of paper significant with a pencil scrawl.

“This method simplifies the production procedure, getsridof the requirement for metal and silicon parts and considerably decreases the ecological footprint of RFID tag production as a result,” PulpaTronics stated.

PulpaTronics approximates its tags will minimize carbon dioxide emissions by 70 per cent compared to requirement RFID tags while halving the associated rate for services.

The business’s 3 co-founders came up with the concept for the RFID tags while working on a group job along with a 4th trainee, Jingyan Chen, as part of their Innovation Design Engineering masters course, collectively run by Imperial College London and the Royal College of Art.

Chloe So, Barna Soma Biro and Rui Ma have various backgrounds, varying from engineering to biological sciences to style style, and desired to combine their abilities to come up with a style that would have a favorable effect on the environment.

“Our method was alittle various to the rest of the groups in our course,” stated Biro, who is PulpaTronics’ tech lead. “We neverever actually began with a issue and then attempted to recognize a option to it as you would typically do in a traditional style procedure.”

“Rather, we examined different types of fascinating innovations that we idea were cutting-edge from a clinical pointofview and then conceptualized around what we might produce out of them by attempting to stay linedup to our worths of decreasing waste and making innovation more available,” he continued.

In addition to the paper circuitry, PulpaTronics likewise used another of these speculative innovations to getridof of the RFID’s microchip, which is accountable for keeping information about the product that is then interacted to the reader